Confidence in Particle Contamination Control

Fastmicro provides surface particle measurement solutions according to ISO14644-9 and ISO14644-17 and other related high-purity standards for sub-micrometer technical cleanliness control. Our product solutions deliver six key benefits to ensure quantitative, consistent, repeatable, and qualified results.

FAST

QUANTITATIVE

EASY TO OPERATE

ACCURATE

CONSISTENT

HIGH THROUGHPUT

Particle Detection Systems

Discover our range of particle counting systems designed for surface particle detection and deposition rate monitoring at sub-micrometer levels across various microtechnology industries and accomplish breakthroughs in cleanliness control with fast, accurate and quantitative surface particle measurements. We enable you to take reliable decisions on where and how to improve cleanliness processes and deliver consistent quality products. And ultimately, reach high-end equipment performance for your end users, improving process quality, manufacturing yield and minimizing product failures.

Fallout Scanner

Monitor particle deposition rates at sub-micrometer levels from 0.5 um and larger, according to ISO 14644-17, in real-time and at the same cleanliness levels as your cleanroom classification. Integrate the high-vacuum Fallout Scanner as OEM module to monitor particle deposition inside a tool.

Defect Inspection System

Multi-application Particle Defect Inspection System creates breakthroughs in top- and bottom-side simultaneous high-throughput particle inspection. Detection of 100 nm particles and up on Si, GaN, Compound and Glass Wafers, EUV Pellicles and Reticles. Manual and Automated tools available

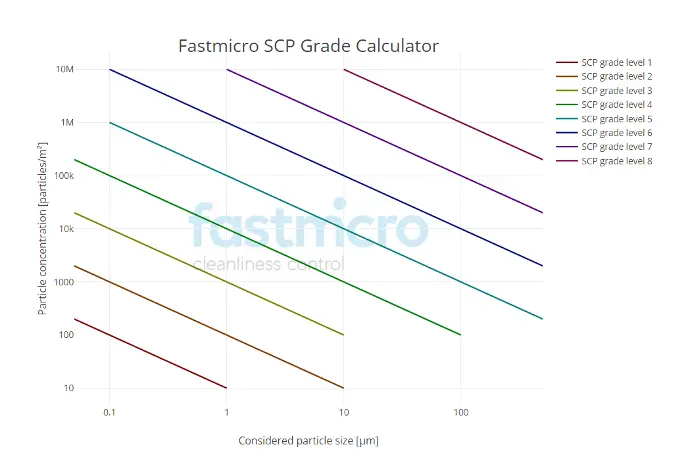

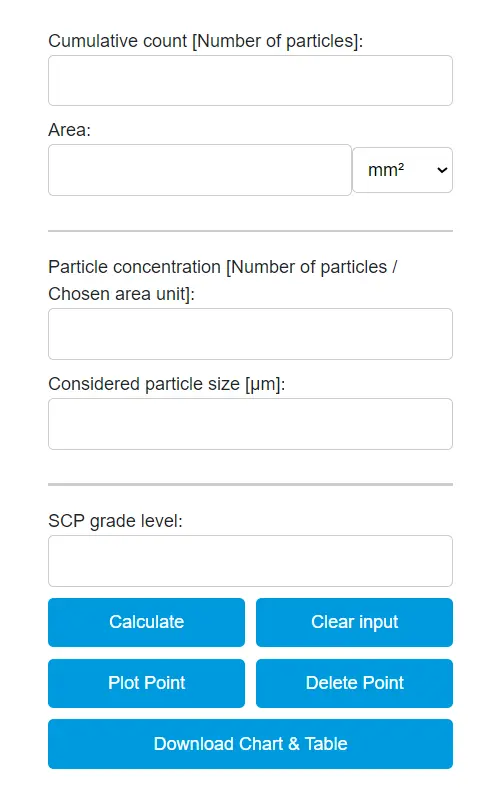

Fastmicro SCP Grade Level Particle Calculator

At Fastmicro, we believe you can accomplish breakthroughs in cleanliness control with fast, accurate and quantitative surface particle measurements. We help our customers to overcome today’s cleanliness challenges in microtechnology by sharing our knowhow and experience.

With the Fastmicro SCP Grade Particle Calculator we enable you to take reliable decisions on where and how to improve cleanliness processes and deliver consistent quality products. And ultimately, reach high-end equipment performance for your end users. Utilize this versatile online tool and downloadable report to simplify complex particle concentration level calculations and corresponding SCP Grade levels according to the ISO 14644-9 standard. Take the step to quantify your particle inspection to understand particle contamination levels and streamline effective decision-making in cleanliness control!

Are you ready to level-up in cleanliness control?

Contact us to start taking particle measurements in seconds.

Knowledge Center

Stay informed with our Knowledge Center, featuring blogs, events, how-to videos, and use cases focused on the latest advancements and practices in particle measurement and contamination control.