FAST

QUANTITATIVE

EASY TO OPERATE

ACCURATE

CONSISTENT

HIGH THROUGHPUT

FM-PDS: multi-application modular platform

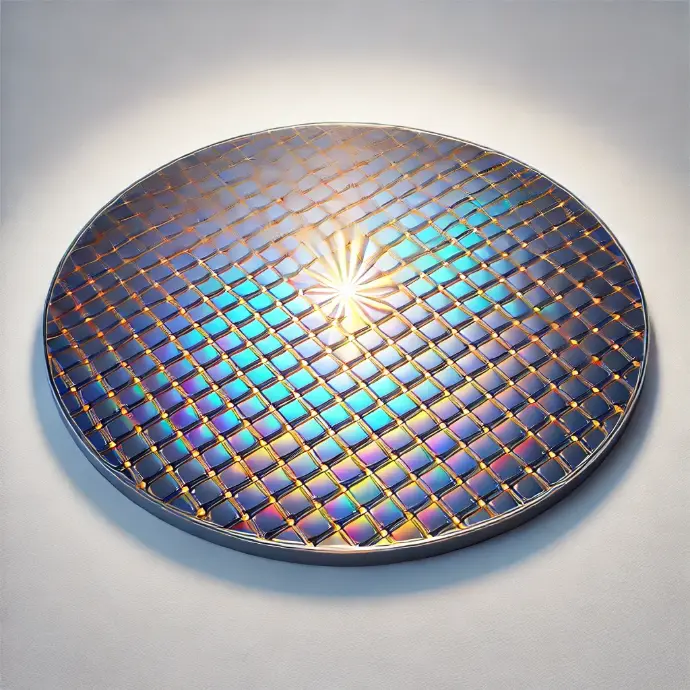

The modular Fastmicro Particle Defect Inspection System metrology platform can be customized to suit each production qualification process or to fit into a production line. This can include manual and automated wafer handling: package openers for inspection and cleaning, filling stations, robot arms, an inspection spot and a port for cleaning.

The Fastmicro system allows for a scaled inspection surface to suit customer needs, without introducing extra imaging time and using limited floor space.

Direct measurements on product surface

The Fastmicro Particle Defect Inspection System has been developed to measure surface particle contamination levels directly on a product surface in any industry. The primary applications are wafer, pellicles and reticles inspection in Semicon, but also substrates, like in the display market.

The Particle Defect Inspection System has a 4 to 12-inch FOV scanning area, with top- & -bottom-side capability, without moving the product in the metrology stage due to its distinct optics design.

The system can be customized, depending on the the surface that needs to be tested. The metrology module is also available as a white label solution for system integrators and OEM’s.

Photomask PDS Applications

High Purity Critical parts

3Di

copper to copper

WAFERS

backside blanks bevels

RETICLES

photomasks backside

PELLICLES

front and backside

Are you ready for the next step in cleanliness control?

Contact us and make your particle measurement in seconds.

Contact Us Now

about anything related to our Photomask Defect Inspection