What Our Customers Say

Our customers are at the heart of everything we do, and their success stories reflect our commitment to excellence in particle measurement and cleanliness control. From small tech startups to large multinational corporations, our clients experience significant improvements in process quality and operational efficiency. These testimonials underscore our role in enhancing industry standards and contributing to the technological advancement of our clients' operations.

Feedback from our diverse client base consistently highlights the precision, reliability, and innovation of our particle measurement systems. Our clients value the tailored solutions and ongoing support that Fastmicro provides, ensuring their equipment performs optimally and aligns with stringent industry regulations. These positive outcomes not only reinforce our leadership in the market but also drive continuous improvement in our technologies and services.

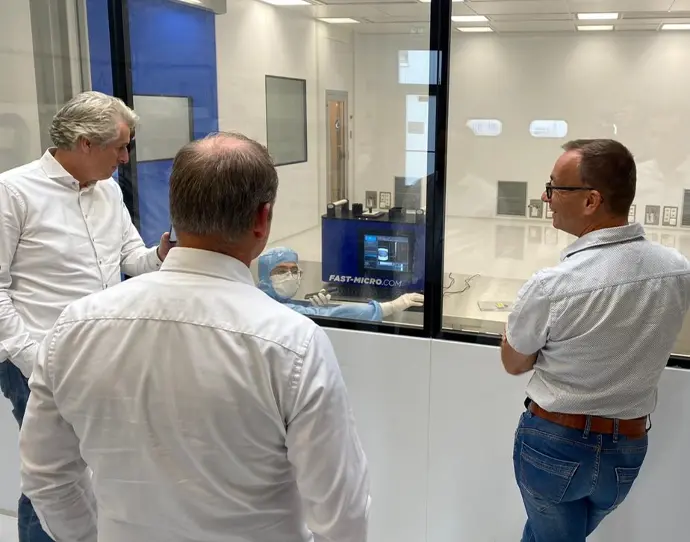

Launching Customer Testimonials

Fastmicro has transformed our inspection capability business significantly. Before migration to this new inspection tool, we saw a 50% variation in the particle count measurements. This is now reduced to less than 10% in combination with a particle detection limit that went down significantly by more than one order of magnitude to 0.5 micrometer. We have confidence in the Fastmicro scanner to help us with finding an excellent quantification of the surface cleanliness of critical parts.

As valued customer, I know that the integration of Fastmicro, has allowed us to reach our required machine defectivity performance.

Besides accurate measurements, the tool offers ease of use and high throughput features. We appreciate the professional service and collaboration with Fastmicro to extend the capabilities of the tool further in the future.

Dr. Ir. L.H.A. Leunissen

ASML, Cleanliness Project Manager

Industry Leader Semicon Litho supports our core technology

Fastmicro has enabled us to significantly speed up our testing and development process by reducing our measurement time by a factor 9.

Ir. Imre Dehner

ASML, Main Delivery Owner Pellicle Defectivity

With Fastmicro’s technology, we’ve strengthened our particle contamination control and are confidently meeting the strict cleanliness standards of the EUV lithography supply chain, essential for achieving high semiconductor yields.

Beyond the tool itself, Fastmicro’s responsive service and support ensure consistent system performance and help us deliver products that enable our customers to maximize device yield"

Pozzetta Inc.

Are you ready for the next step in cleanliness control?

Contact us and make your particle measurement in seconds.

Discover our Particle Counting Products

Learn more about our comprehensive range of particle measurement products designed for precise, reliable cleanliness control. Each product is developed with the latest technology to meet the high standards of our clients, ensuring superior performance in demanding environments. Whether you're looking for a system to enhance semiconductor production or need a solution for technical cleanliness in pharmaceutical manufacturing, Fastmicro has the right tools to help your business succeed.

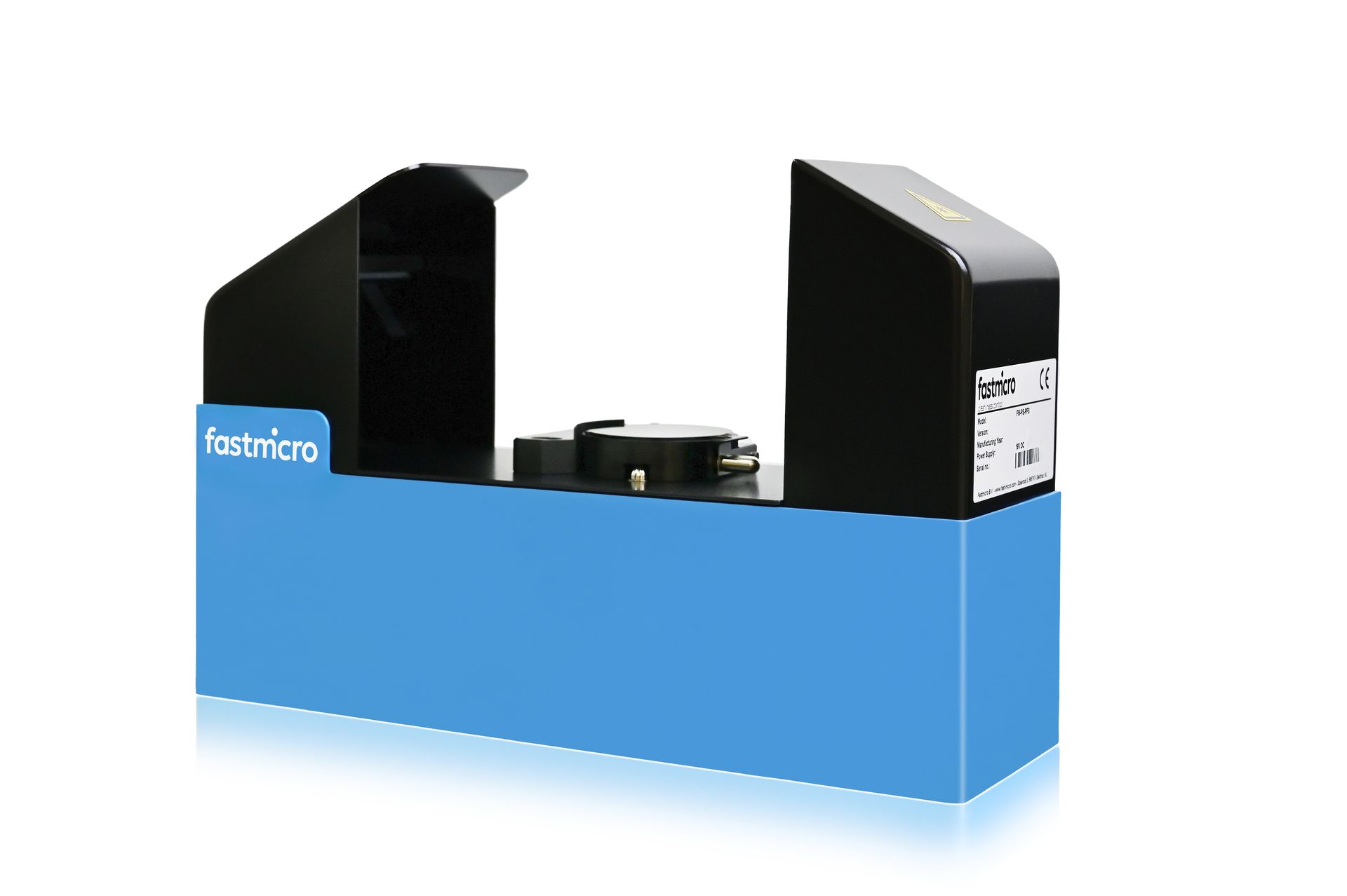

Sample Scanner

Measure sub-micrometer surface particle contamination levels from 0.5 um and larger, according to ISO 14644-9 and other norms. Scans indirect 'tape-life' Samplers for taking and collecting particle contamination samples from diverse product surfaces and assemblies.

Fallout Scanners

Monitor particle deposition rates at sub-micrometer levels from 0.5 um and larger, according to ISO 14644-17, in real-time and at the same cleanliness levels as your cleanroom classification. Integrate the high-vacuum Fallout Scanner as OEM module to monitor particle deposition inside a tool.

Defect Inspection Systems

Multi-application, fixed FOV inspection system creates breakthroughs in high-throughput particle inspection down to 100 nm particles on Si, GaN, Glass Wafers, EUV Pellicles and Reticles, and other critical components requiring high-purity levels. Enables testing top- and bottom-side simultaneously.