What Are Particles?

Types of Particles

A particle refers to a minute entity, either solid or liquid, suspended in a medium such as air, liquid, or gas. These entities can range from microscopic to visible to the naked eye. Particles can be natural, like dust or pollen, or synthetic, such as microplastics. In scientific contexts, particles are fundamental units of matter and can exhibit diverse behaviours, including diffusion and aggregation. Understanding particle properties, such as size, shape and composition, is crucial in various disciplines, from physics and chemistry to environmental science and engineering, where they influence processes, material properties, and environmental quality.

Particles are everywhere. They could be the solid dust on your keyboard. They could be the liquid droplets in your perfume spray. They could simply be in the gaseous air vapor that you breathe in.

Particles are easily seen in the common materials around us. They are in the powders and granules in our kitchen or in the cleaning items in our households. In nature, particles exist in desirable forms like beach sand or snowflakes. Some can be undesirable like volcanic ash, mud or pollens. Biological organisms contain cells, proteins, viruses, microbes which are also sometimes referred to as particles. From these examples, we can define particles as any form of matter with physical dimensions, which are not always visible to the naked eye. Particles can be one million times smaller than a hair strand.

Impact of Particles

But even though they are minute, particles can still have a huge impact on humanity. Manmade particles and particulate systems have greatly improved everyday life. Profound improvements on health and welfare are some of the direct benefits of particles in pharmaceuticals, for example. However, there are certain circumstances wherein particles can also have detrimental effects. Particulate emissions from combustion, water pollution and other waste from industrial processes are harmful not only to humans but also to the environment and other life forms.

What is Particle Contamination?

Particle contamination refers to the presence of unwanted solid or liquid particles in a controlled environment, such as cleanroom or manufacturing facility. These contaminants can originate from various sources, including human activities, machinery, or external environments. Particle contamination poses significant risks to sensitive processes and products, potentially compromising quality, reliability, and safety. Industries such as semiconductor manufacturing, pharmaceuticals, and biotechnology prioritize minimizing particle contamination to maintain product integrity and meet regulatory standards. Mitigation strategies include advanced filtration systems, controlled airflow, and strict cleanliness protocols. Monitoring and managing particle contamination are essential for ensuring optimal performance and compliance in critical environments.

What is Particle Cleanliness?

Particle cleanliness refers to the level of contamination by solid or liquid particles in a given environment, typically measured in terms of particle concentration per volume of air. This concept is particularly significant in controlled environments like cleanrooms, where minimizing particle contamination is essential for ensuring product quality, reliability, and safety. Particle cleanliness standards, such as those outlined in ISO 14644, classify environments based on allowable particle counts at various ranges. Maintaining optimal particle cleanliness involves implementing stringent cleanliness protocols, advanced filtration systems, and regular monitoring to meet industry-specific requirements and regulatory standards, thus safeguarding critical processes and products against contamination risks.

Importance of Particle Cleanliness Control

These particles, although minute, could have great impact on several industries. Consequently, particle cleanliness control plays a crucial role in microtechnology industries such as front-end semiconductors, automotive, aerospace, and life sciences. In these industries, even small particles can have significant impacts on product quality and performance. Cleanrooms and controlled environments are established to provide for the control of contamination of air and surfaces to levels appropriate for accomplishing contamination-sensitive activities. Contamination control can be beneficial for protection of product or process integrity in applications such as aerospace, microelectronics, pharmaceuticals, medical devices, healthcare and food.

Learn more

Discover Our Products for Complying to ISO Standards Now!

Are you looking for products that adhere to the highest cleanliness and quality standards? Explore our range of solutions designed to meet ISO 14644 Standards.

Overview of ISO 14644 Standards

ISO 14644 is a globally recognized standard that provides guidelines for the classification of air cleanliness in cleanrooms and controlled environments. Developed by the International Organization for Standardization (ISO), this standard establishes uniform criteria for airborne particle concentrations based on particle size. It outlines methods for monitoring, testing and maintaining cleanroom environments to ensure compliance with specified cleanliness levels. ISO 14644 is crucial for industries requiring stringent environmental control, such as pharmaceuticals, electronics, and healthcare. By adhering to this standard, organizations can optimize production processes, enhance product quality, and mitigate contamination risks, ultimately fostering a safer and more reliable working environment. The ISO 14644 series of standards help ensure that products meet stringent cleanliness requirements, leading to improved reliability and customer satisfaction.

ISO 14644-1 Airborne Particulate Cleanliness

ISO 14644:1 serves as the foundational standard for cleanroom and controlled environment classifications, defining particle cleanliness levels based on airborne particulate contamination. It establishes criteria for cleanroom design, operation, and monitoring, vital for industries such as pharmaceuticals and electronics.

ISO 14644-9 Surface Cleanliness

On the other hand, ISO 14644:9 focuses specifically on the classification of surface cleanliness by addressing the measurement and assessment of particle and chemical cleanliness on surfaces. Together, these ISO standards provide comprehensive guidelines for maintaining optimal airborne and surface cleanliness in controlled environments, ensuring adherence to stringent quality and regulatory requirements across diverse sectors reliant on contamination control.

ISO 14644-9:2022 Surface Cleanliness Procedures and Guidelines

ISO 14644-9:2022 establishes a procedure for the assessment of surface cleanliness by particle concentration (SCP) for particle size between 0.05mm and 500 mm. It is applied to all solid surfaces in cleanrooms and associated controlled environments, such as walls, ceilings, floors, working environments, tools, equipment and products. It explains the surface cleanliness level assessment system and illustrates the ISO-SCP grading level format.

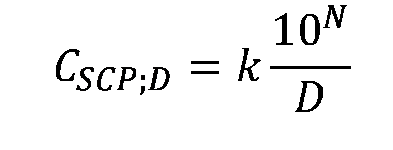

The degree of SCP in a cleanroom or associated controlled environment is designated by a cleanliness level grading number, N, specifying the maximum total particle concentration on surfaces permitted for a considered particle size.

were

Cscp;D : the

maximum permitted total surface concentration, in particles per square meter of

surface, of particles that are equal to or larger than the considered particle

size; rounded to the nearest whole number, using no more than three significant

figures.

N : the SCP cleanliness level grading number, which is limited to SCP grade level 1 to SCP grade level 8; the SCP grade level number N is qualified by the measured particle diameter D, in micrometers.

D : the considered particle size, in micrometers.

K : a constant 1, in micrometers.

An example of table of calculated values for the maximum surface particle concentration on an area of 1 m2 for every SCP level is given in the ISO 14644-9:2022 document.

Calculate Free Now

Try Fastmicro Particle Calculator Tools Today!

A Fastmicro calculator tool can be used for determining SCP level for a particular particle concentration

Stay Informed and Up to Date

Understanding particle cleanliness and adhering to ISO standards are crucial for maintaining the quality and safety of your products and processes. Stay ahead of industry trends and best practices by subscribing to our newsletter. Get the latest updates, expert insights, and exclusive content delivered straight to your inbox.