Particle Size Analyzer

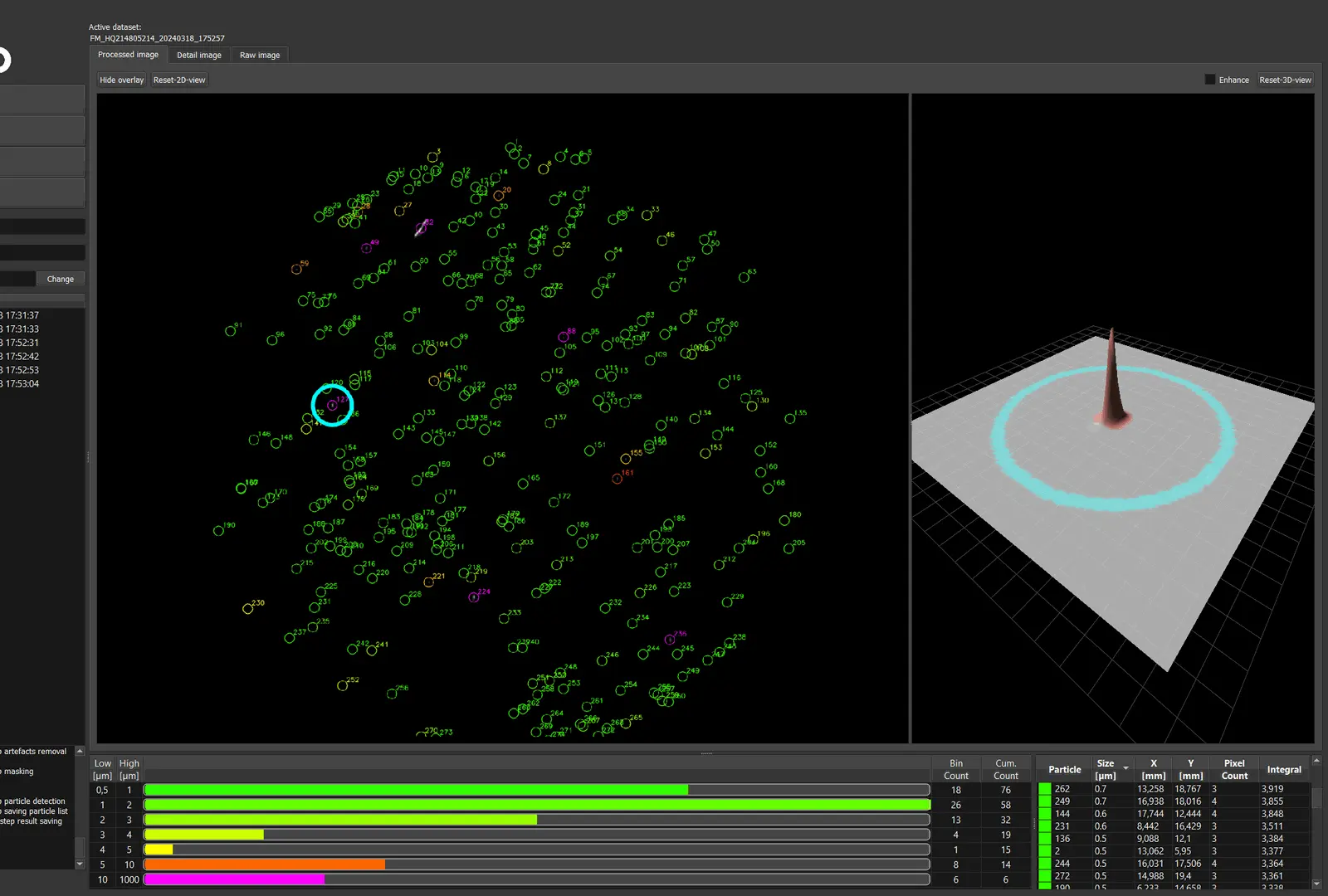

The Fastmicro Sample Scanner is an inspection tool for indirect Surface Particle Measurement contamination down to 0.5 micrometer particles using innovative 'tape-lift' samplers. Quick and efficient, the Particle Size Scanner analyzes samples within seconds over a sample area of 225 mm², ensuring immediate and accurate results.

The versatility of the Sample Scanner is enhanced with different sampler options, including the card sampler holder for indirect measurements and the 1” wafer holder for fallout measurements. This adaptability makes it suitable to test diverse situations across various industries, providing robust measurements and valuable insights into contamination levels.

Cleanroom Particle Counter: Fastmicro Sample Scanner Applications

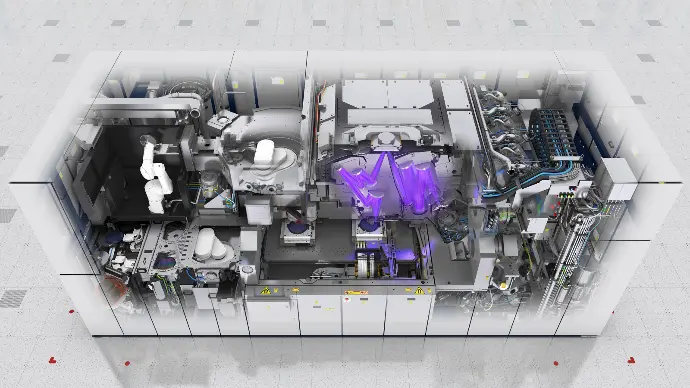

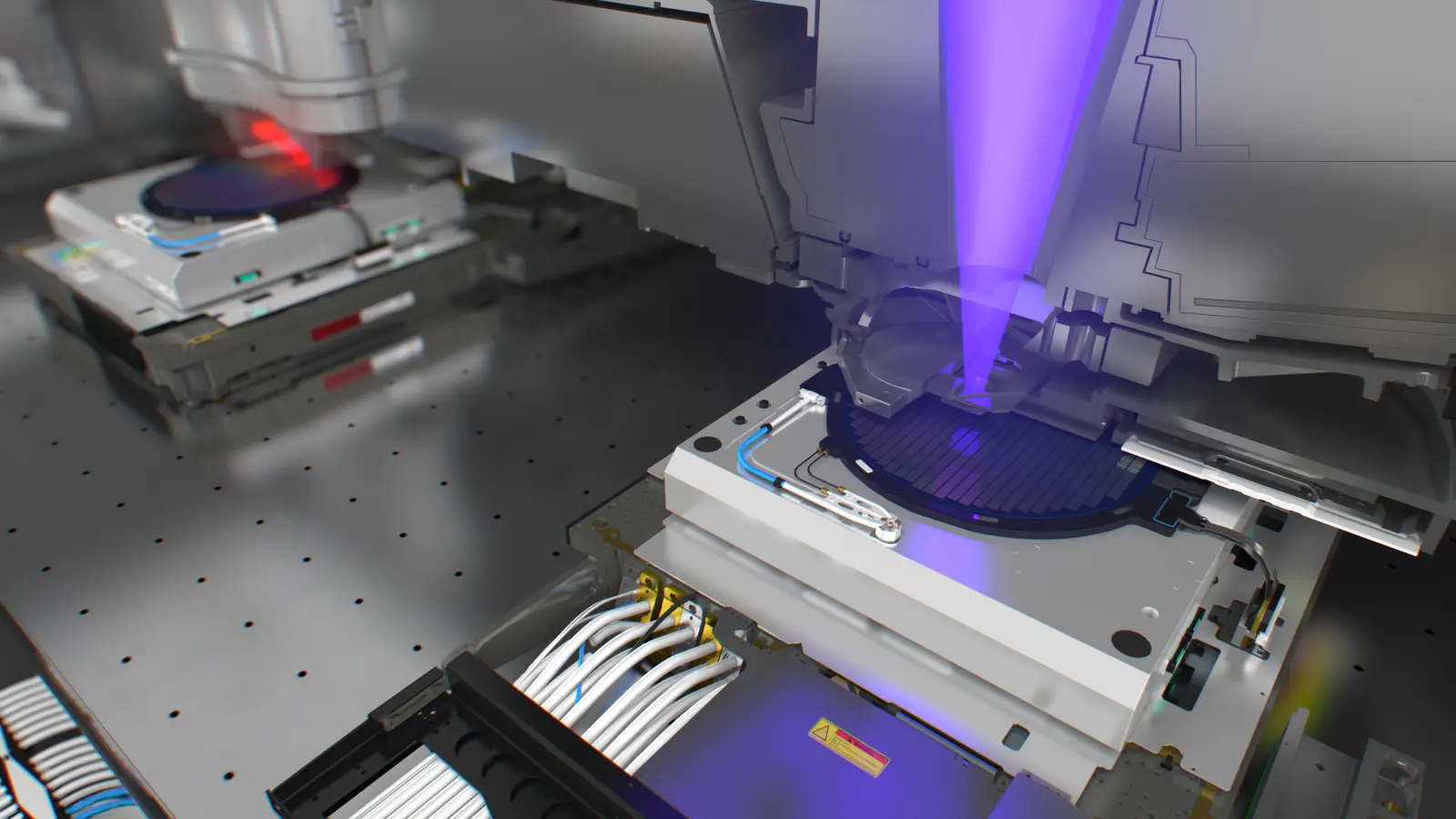

EQUIPMENT

ASSEMBLIES

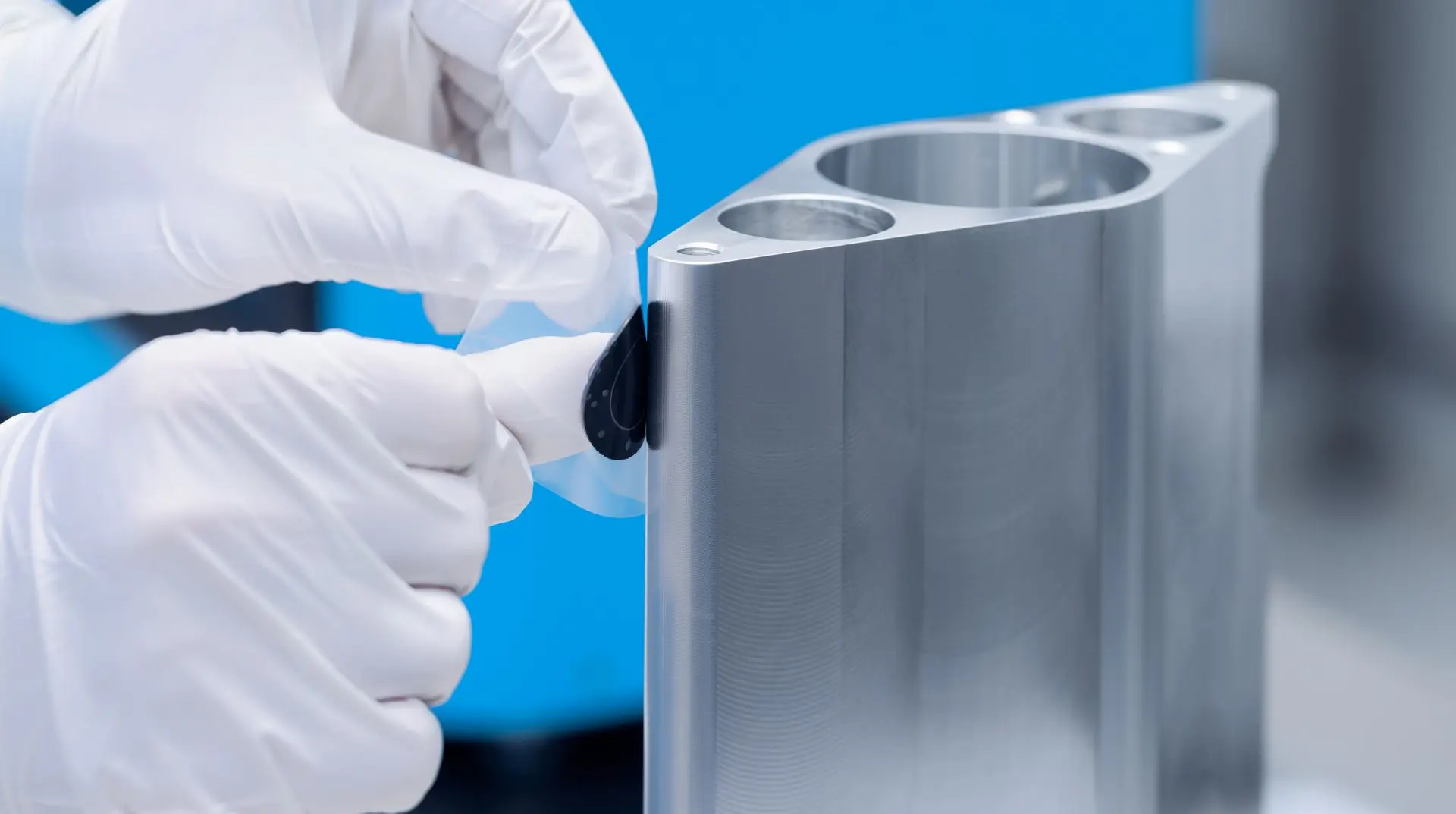

PARTS

CLEANING

Particle Measurement: Workflow for the Fastmicro Sample Scanner

Particle Size Analysis on parts and in assemblies is possible on flat, curved and cavity surfaces

1. Particle Sampling with PMC

1. Particle Sampling with PMC

2. Particle Measurement and Detection

3. Particle Counter, Particle Size and Position in Seconds

3. Particle Counter, Particle Size and Position in Seconds

Are you ready for the next step in Particle Size Analysis?

Contact us and make your Particle Measurement in seconds.

Particle Counter: Sample Scanner Specifications

Fast and High Production Throughput |

|

Data Output |

|

Easy to Operate |

|

Particle Detection Range |

|

Reproducibility |

|

Particle Sizing accuracy |

|

Nondestructive – no cross contamination to samples |

|

Requirements on sampler and sample handling |

|

Size & weight |

|

Model |

|

Contact Us Now

about anything related to our Particle Size Analyzer: Fastmicro Sample Scanner.